A cikin Tsarin injin CNC, kayan filastik suna taka muhimmiyar rawa wajen ƙirƙira ingantattun abubuwan haɗin gwiwa don ɗimbin aikace-aikace.Daga samfura zuwa sassan amfani na ƙarshe, zaɓin kayan filastik da ya dace shine mafi mahimmanci don cimma ayyukan da ake so, karɓuwa, da ingancin farashi.A cikin wannan jagorar, za mu bincika kayan filastik CNC guda biyar da aka saba amfani da su - ABS, PC, Nylon, PMMA, da UHMW-PE - kuma mu ba da haske kan yadda za a zaɓi ingantaccen abu don aikinku.

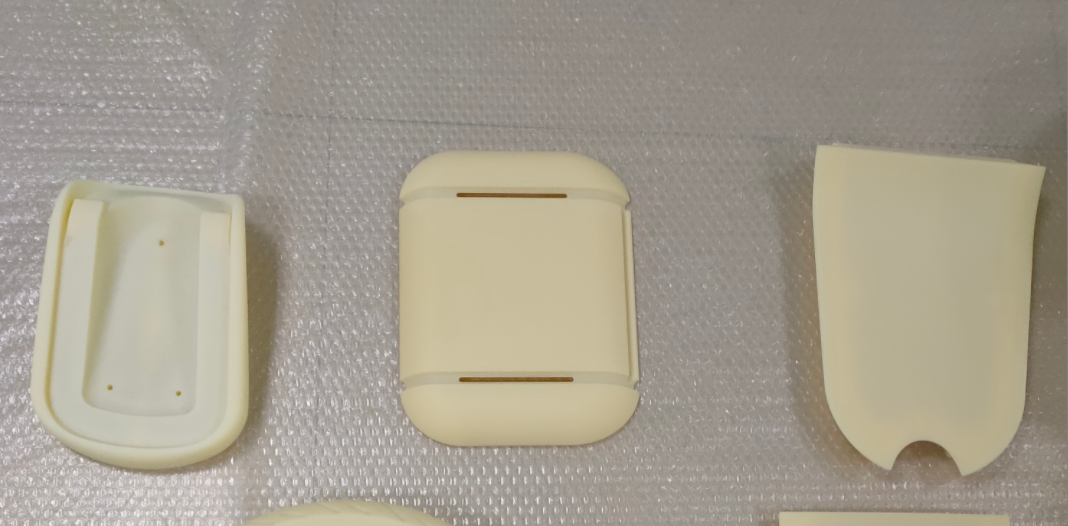

1. ABS (Acrylonitrile Butadiene Styrene)

ABS shine madaidaicin thermoplastic wanda aka sani don kyakkyawan juriya na tasiri, dorewa, da injina.Ga abin da za ku yi la'akari lokacin zabar ABS don aikin ku na CNC:

Aikace-aikace: ABS ya dace da aikace-aikace da yawa, gami da sassan mota, kayan masarufi, da samfuri.

Kayayyakin: Yana ba da ƙarfin injina mai kyau, juriya mai ƙarfi, kuma ana iya sarrafa shi cikin sauƙi zuwa madaidaicin haƙuri.

La'akari: Yayin da ABS ke ba da kyakkyawan aikin gabaɗaya, ƙila ba shine mafi kyawun zaɓi don aikace-aikacen da ke buƙatar juriya mai zafi ko juriya na sinadarai ba.

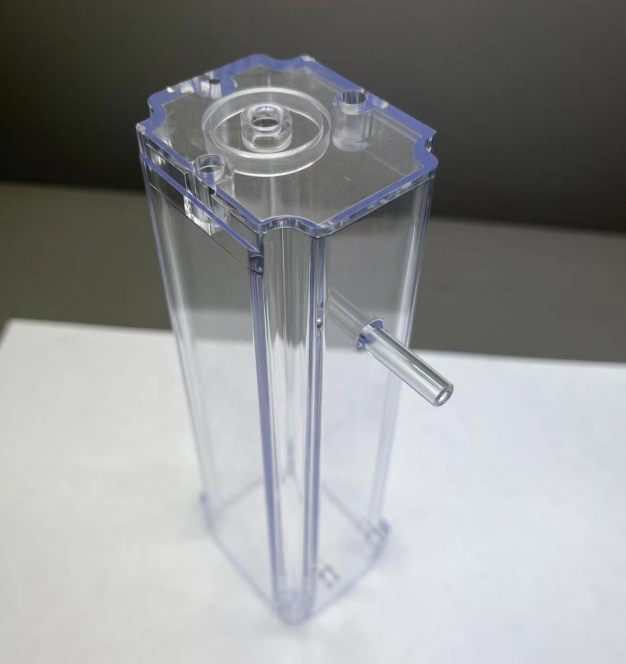

2. PC (Polycarbonate)

Polycarbonate shine madaidaicin thermoplastic mai daraja don juriyar tasirin sa na musamman da tsayuwar gani.Anan akwai mahimman la'akari don zaɓar PC:

Aikace-aikace: PC yawanci ana amfani da shi a aikace-aikace kamar kayan aikin aminci, shingen lantarki, da kayan haɗin mota.

Properties: Yana fahariya babban tasiri ƙarfi, m gaskiya, kuma mai kyau zafi juriya.

La'akari: PC na iya zama mafi ƙalubale ga na'ura idan aka kwatanta da sauran robobi saboda taurinsa da halinsa na samar da kwakwalwan kwamfuta a lokacin machining.

3. Nailan (Polyamide)

Nylon babban injin thermoplastic ne wanda ya shahara saboda ƙarfinsa, ƙarfi, da juriya na sinadarai.Ga abin da za ku tuna lokacin zabar Nylon don mashin ɗin CNC:

Aikace-aikacen: Nailan shine manufa don aikace-aikacen da ke buƙatar ƙarfi mai ƙarfi, kamar gears, bearings, da abubuwan haɗin ginin.

Kayayyakin: Yana ba da kyakkyawan juriya na abrasion, ƙarancin juriya, da ingantaccen juriya na sinadarai.

La'akari: Nailan yana shayar da danshi, wanda zai iya shafar kwanciyar hankali da daidaiton mashin ɗin idan ba a yi la'akari da shi yadda ya kamata ba yayin aikin CNC.

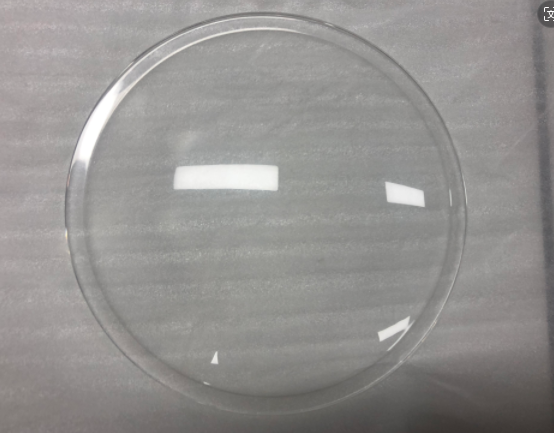

4. PMMA (Polymethyl Methacrylate)

PMMA, wanda aka fi sani da acrylic, shine madaidaicin thermoplastic mai ƙima don tsayuwar gani da sauƙi na inji.Yi la'akari da waɗannan lokacin zabar PMMA don aikin CNC ɗin ku:

Aikace-aikace: Ana amfani da PMMA sau da yawa a cikin sigina, abubuwan nuni, abubuwan haɗin gani, da na'urorin haske.

Kayayyaki: Yana ba da kyakkyawan haske na gani, juriya mai kyau, kuma ana iya sarrafa shi cikin sauƙi zuwa rikitattun siffofi.

La'akari: PMMA yana da wuyar yin ɓarna kuma yana iya nuna ƙarancin juriya ga wasu kaushi da masu tsaftacewa.

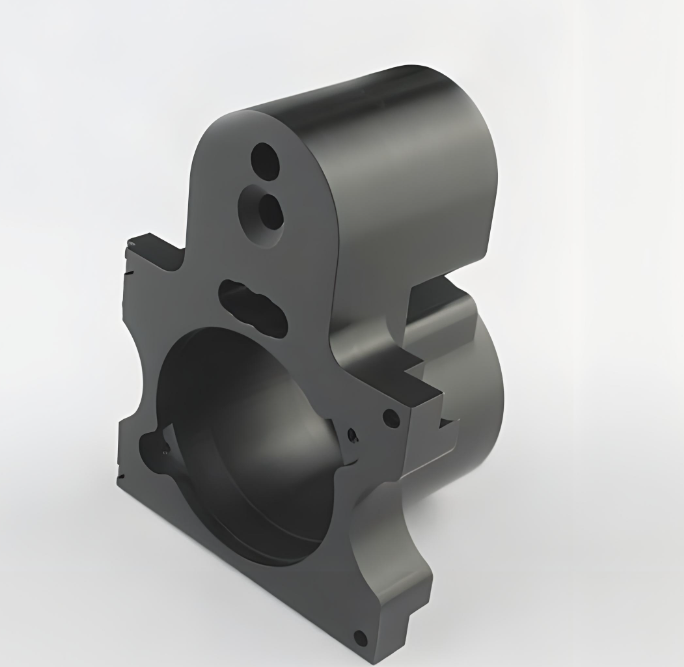

5. UHMW-PE (Ultra-High Molecular Weight Polyethylene)

UHMW-PE babban aikin thermoplastic ne wanda aka sani don juriyar sawa na musamman, ƙarancin juzu'i, da kaddarorin sa mai.Ga abin da za ku yi la'akari lokacin zabar UHMW-PE:

Aikace-aikace: UHMW-PE ana yawan amfani dashi a aikace-aikacen da ke buƙatar ƙananan juzu'i, kamar abubuwan jigilar kaya, bearings, da sawa tube.

Properties: Yana bayar da fice lalacewa juriya, high tasiri ƙarfi, da kuma m sinadaran juriya.

Mahimmanci: UHMW-PE na iya zama mafi ƙalubale ga na'ura saboda girman nauyin kwayoyin sa da kuma yanayin samar da kwakwalwan kwamfuta masu tsini yayin aikin injiniya.

Lokacin zabar abin da ya dace na filastik CNC don aikinku, yana da mahimmanci a yi la'akari da hankali abubuwa kamar buƙatun aikace-aikacen, kaddarorin kayan aiki, da la'akari da machining.Ta hanyar fahimtar keɓantattun halaye na ABS, PC, Nylon, PMMA, da UHMW-PE, zaku iya yanke shawarar yanke shawara waɗanda ke haɓaka aiki, dorewa, da ingancin farashi don ƙoƙarin injin ku na CNC.Ko kuna ƙirƙira samfura, sassa na al'ada, ko samfuran amfani na ƙarshe, zaɓin ingantaccen kayan filastik yana kafa tushe don nasara a tafiyar masana'anta.

Lokacin aikawa: Maris 26-2024