Lokacin da ya zo ga kera sassan filastik, zaɓin tsarin da ya dace yana da mahimmanci don tabbatar da inganci, ƙimar farashi, da inganci.Shahararrun hanyoyi guda biyu don samar da sassan filastik sune simintin urethane da gyare-gyaren allura.Dukansu suna da fa'idodi na musamman da aikace-aikacen su, amma zaɓin mafi kyawun aikin ku ya dogara da dalilai daban-daban.A cikin wannan rukunin yanar gizon, za mu bincika bambance-bambance, fa'idodi, da madaidaitan shari'o'in amfani don simintin gyare-gyaren urethane da gyare-gyaren allura don taimaka muku yanke shawarar da aka sani.

Fahimtar urethane Casting

Yin simintin urethanewani tsari ne na masana'antu inda aka zuba polyurethane ruwa a cikin siliki na silicone don ƙirƙirar sassa.Wannan hanya ita ce manufa don samar da ƙananan ƙananan sassa da samfurori tare da babban aminci da cikakkun bayanai.

Amfanin Simintin gyare-gyare na urethane:

Mai Tasirin Kuɗi don Ƙarfin Ƙarfafawa:Simintin gyare-gyare na urethane yana da tattalin arziki don samar da ƙananan batches, yana mai da shi kyakkyawan zaɓi don samfurori da gajeren ayyukan samarwa.

Lokacin Saurin Juyawa:Tare da simintin gyare-gyaren urethane, shirye-shiryen mold da tsarin samarwa suna da sauri sosai, suna ba da damar yin samfuri da sauri.

Babban Dalla-dalla da Ƙarshen Ƙarshe:Yin simintin gyare-gyare na urethane na iya samar da sassa tare da cikakkun bayanai masu rikitarwa da ƙarewar ƙasa mai santsi, suna kwaikwayi sassan samarwa na ƙarshe.

Izinin Kayan aiki:Akwai nau'ikan kayan urethane da yawa, suna ba da kaddarori daban-daban kamar sassauci, tauri, da karko.

Ƙananan Farashin Kayan aiki:Silicone gyare-gyaren da ake amfani da su a cikin simintin urethane ba su da tsada don samarwa idan aka kwatanta da karfen da ake bukata don gyaran allura.

Ingantattun Aikace-aikace don Simintin Urethan:

• Samfuran samfuri da samfuran ra'ayi

• Sassa na al'ada don samar da ƙananan ƙira

• Gwajin kafin samarwa

• Gwajin aiki na sassa masu hadaddun geometries

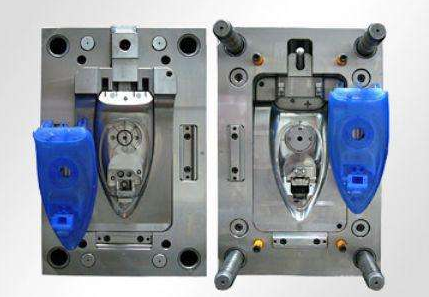

Fahimtar Gyaran Injection

Yin gyare-gyaren allura wani tsari ne na masana'antu inda ake zuba robobin da aka narkar da shi a cikin wani ƙarfe na ƙarfe a ƙarƙashin matsa lamba don samar da sassa.Wannan hanyar tana da inganci sosai don samarwa da yawa kuma tana iya samar da sassa tare da daidaiton inganci da madaidaici.

Amfanin Gyaran allura:

Tasirin Kuɗi don Ƙarfafa Ƙarfafawa:Yayin da farashin kayan aiki na farko ya yi yawa, gyare-gyaren allura ya zama mafi arziƙi don manyan ayyukan samarwa saboda ƙananan farashin kowane ɓangare.

Maɗaukakin Maɗaukaki da daidaito:Yin gyare-gyaren allura yana ba da kyakkyawar maimaitawa, yana tabbatar da cewa kowane ɓangaren da aka samar daidai yake kuma ya dace da ingantattun matakan inganci.

Faɗin Kayayyakin:Za a iya amfani da ɗimbin yawa na thermoplastics a cikin gyare-gyaren allura, samar da zaɓuɓɓuka don sassan da ke buƙatar takamaiman kaddarorin inji da aiki.

Ingantacciyar Ƙira:Yin gyare-gyaren allura na iya samar da dubban sassa a cikin ɗan gajeren lokaci, yana mai da shi manufa don masana'anta mai girma.

Dorewa da Tsawon Rayuwa:Ƙarfe na ƙarfe da aka yi amfani da shi wajen yin gyare-gyaren allura yana da ɗorewa kuma yana iya samar da adadi mai yawa kafin buƙatar kulawa ko sauyawa.

Ingantattun Aikace-aikace don Gyaran allura:

•Maɗaukakiyar samar da sassa na filastik

• Kayayyakin masu amfani da lantarki

• Abubuwan da ke cikin mota

• Na'urorin likitanci da marufi

• Sassan masana'antu da kasuwanci

Kwatanta Simintin gyare-gyaren urethane da gyare-gyaren allura

Farashin:

•Urethane Casting:Ƙananan farashin farko da kuɗin kayan aiki;farashi-tasiri don samar da ƙananan ƙira.

•Gyaran allura:Haɓaka farashin kayan aiki na farko amma ƙananan farashin kowane bangare don manyan ayyukan samarwa.

Girman samarwa:

•Urethane Casting:Mafi dacewa don ƙananan ƙarami zuwa matsakaici (1-1000 sassa).

•Gyaran allura:Mafi dacewa don samarwa mai girma (1000+ sassa).

Lokacin Jagora:

•Urethane Casting:Mafi saurin lokacin jagora don ƙananan batches da samfura.

•Gyaran allura:Tsawon lokacin jagora saboda ƙirar ƙirƙira amma samarwa da sauri don babban kundin.

Cikakkun Sashe da Ciki:

•Urethane Casting:Mafi kyau ga hadaddun geometrics da cikakkun bayanai.

•Gyaran allura:Ƙarfin madaidaici amma yana iya buƙatar ƙira mai ƙima da tsada don rikitattun sassa.

Zaɓin Tsarin Da Ya dace don Aikinku

Shawarar tsakanin simintin gyare-gyaren urethane da gyare-gyaren allura ya dogara da abubuwa da yawa:

•Girman samarwa:Don ƙananan ƙarami zuwa matsakaici, simintin urethane ya fi tasiri.Don samar da girma mai girma, yin gyare-gyaren allura shine mafi kyawun zaɓi.

•Kasafin kudi:Yi la'akari da farashin kayan aiki na farko da farashin kowane ɓangare.Simintin urethane yana buƙatar ƙaramin saka hannun jari na gaba.

•Lokacin Jagora:Idan kuna buƙatar juyawa da sauri don samfura ko gajeriyar gudu, simintin urethane yana ba da saurin lokacin jagora.

•Rukunin Sashe:Simintin gyare-gyaren urethane ya yi fice wajen samar da sassan da ke da cikakkun bayanai, yayin da yin gyare-gyaren allura yana ba da daidaito mai yawa ga adadi mai yawa.

•Abubuwan Kayayyaki:Yi ƙididdige ƙayyadaddun ƙayyadaddun buƙatun kayan don sassan ku kuma zaɓi tsarin da ke ba da mafi kyawun zaɓin kayan.

Kammalawa

Dukansu simintin gyare-gyaren urethane da gyare-gyaren allura suna da fa'idodi daban-daban kuma sun dace da buƙatun aikin daban-daban.Ta hanyar fahimtar ƙarfi da iyakoki na kowane tsari, zaku iya yanke shawara mai fa'ida wacce ta dace da buƙatun aikinku, kasafin kuɗi, da tsarin lokaci.Ko kuna buƙatar samfura masu ƙima ko manyan samarwa, zaɓar hanyar masana'anta da ta dace zai tabbatar da nasarar aikin ku.

Lokacin aikawa: Juni-14-2024